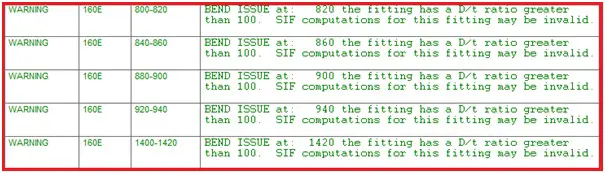

Sometimes while working you may have come across situations when the pipe diameter to thickness ratio becomes more than 100. These normally happen for very large-size low-pressure systems. Due to low design pressure (of the order of 1 bar to 3 bar) calculated thickness is less. For example, consider a flare line of 42-inch (or 48 inches) NPS with 3-bar design pressure. The selected thickness is STD wall thickness i.e, 9.525 mm. So the Diameter to thickness ratio is more than 100. Normally Caesar II is widely used for stress analysis of all piping systems. But when you use the software for stress analysis of such stress systems you will find a warning message similar to as shown in Fig. 1. This warning message is generated for all Bend and Intersections in the pipe.

So whether you should proceed with pipe stress analysis ignoring such warning messages. ASME B31.3 does not provide any equation for calculating the SIF values for lines with D/t exceeding 100 (Also known as thin-walled pipes). This restriction on D/t comes from the B31.1 and B31.3 piping codes because they do not have computations for stress intensification factors above this threshold, largely because the testing that was done by Markl had this same limitation. CAESAR II will continue to use the existing code formulations for SIF calculation when a D/t ratio is greater than 100, but no one knows if these relations are still valid. That is the reason Caesar II displays such a warning.

CAESAR II is a pipe flexibility analysis software package and as with all such packages, there are limitations that should not be exceeded. It is always better to use some sort of FEA analysis for analyzing such systems and you will get accurate results. But considering the number of such stress systems in any project (hardly one or two) purchasing costly FEA software may not get the project approval. So in such a situation, you may not have other options than to use Caesar II. So the analyst can use Caesar II, but he needs to always bear the following points in mind:

Failure of thin wall piping is dominated by the buckling phenomenon and the validity of the flexibility analysis assumptions decreases. CAESAR II and other such flexibility analysis programs (CAEPIPE, AUTOPIPE, etc.) do not compute buckling because it is a localized effect caused by imperfections in the manufacture, uneven corrosion, pitting, or other defects. CAESAR II considers the pipe to be homogeneous in cross-section with an even wall thickness everywhere. So the analyst is encouraged to consider buckling separately from the CAESAR II analysis for such systems.

Another problem with the very thin-walled pipe is local deformation in the region of restraint. When significant local deformation is likely at restraint locations, the load distribution will no longer follow expectations as with homogeneous cross-sections and standard flexibility analysis results should not be relied on. Normally it is a standard practice to use wear pads in all support locations to reduce the possibility of local deformation at restraint points.

It is better to use a lowered allowable stress than what is allowed by the piping code in use. For example, the analyst can reduce the allowable value by 75% of the code allowable.

It is better to multiply the Caesar calculated SIF at intersections by 2.5-3.0 and input the same manually at all three node points (Branch and header).

So whether to use Caesar II or not solely depends on the Pipe Stress Engineer. He must discuss the situation with the client and if the client approves then he may proceed with the same. However, recent FEA packages that come along with the latest Caesar II software editions can accurately calculate the SIF values and can be used.

Few more Resources for you..

Stress Analysis Basics

Stress Analysis using Caesar II

Stress Analysis using Start-Prof

Piping Design and Layout

Hi,

regarding the last two bullets, is there any code/standard validating those values? I mean 0.75 times allowable loads and 2-3 times SIF.

Thanks in advance e ciao

Hi sir,

I am unable to get the local deformations in restraint locations in thin walled pipes. What is the major cause for the local deformations in restraint points or how the the deformations start at those locations…

Thanks & Regards

Sathya

Nice & well written

Hi,

Easy to read and very clarifying.

Please could you inform where on B31.3 it says that the ratio must be smaller than 100?

Thanks.

Hello,

I commend you on making this blog; as engineers, making something like this does not typically come very naturally with our interests and so its great to find a resource like this that is so easily accessible and filled with insight.

Thanks for your efforts.