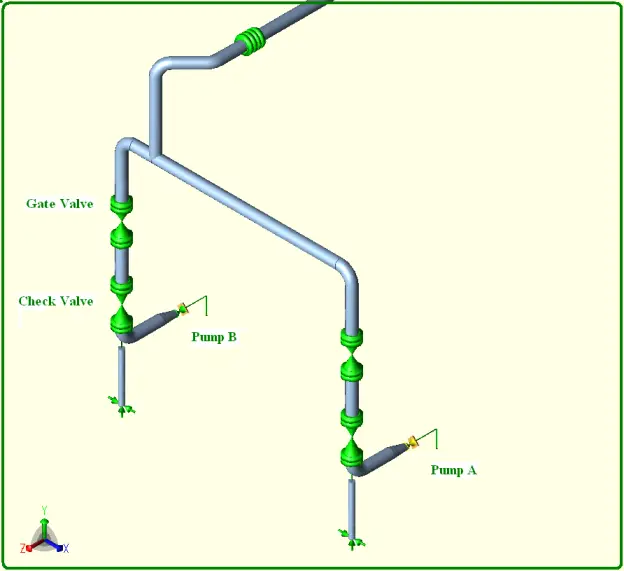

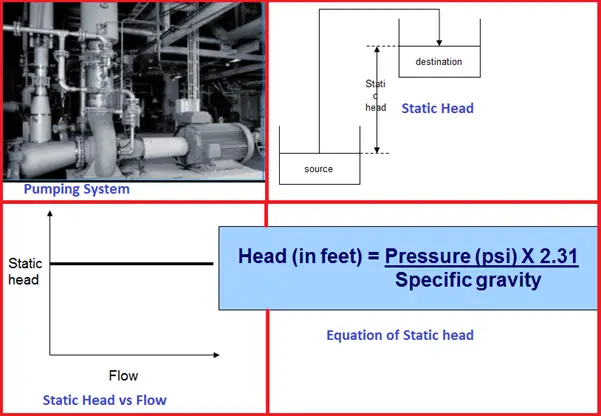

Every power or process piping industry uses several pumps in each unit. The analysis of pump-connected piping systems is considered very critical. In this article, I will try to elaborate on the method followed for the stress analysis of a centrifugal pump piping system. The stress system consists of typical discharge lines of two centrifugal pumps (Pump A and Pump B). Fluid from these two pumps is pumped into a heat exchanger. As per P&ID, only one pump will operate at a time, other pumps will be a stand-by pump. I will explain the stress analysis methodology in three parts:

- 1) Modeling of Pump

- 2) Preparation of analysis Load cases and

- 3) Analyzing the output results.

Modeling of Pump in Caesar II

For modeling the pump we require a vendor general arrangement drawing or outline drawing. All rotary equipment is modeled as a weightless rigid body in Caesar II. From the outline drawing, we need to take the dimensions to some fixed point. Let us take the example of the outline drawing shown in figure 2.

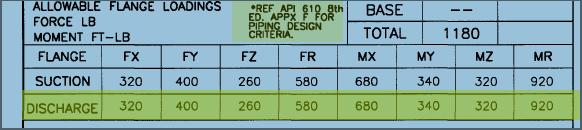

From the above drawing, we can get the dimensions for elements 10-5000 as 8.5 inches and elements 5000-5020 as 6.19 inches. At node 5020 we will provide a fixed anchor. During the modeling of the above elements, we need to use line size and thickness as the diameter and thickness of the equipment. Line temperature and pressures as equipment properties. We have to provide an anchor (with a C-Node) at node 10 for checking nozzle loads which we will compare with the allowable value as provided in Fig. 3 below:

In absence of allowable load value, the Pump design code (API 610 for API pumps, ANSI HI 9.6.2 for non-API pumps) can be followed for the same.

After the pump is modeled as a rigid body the piping modeling need to be done from pump-piping interconnection flanges.

Preparation of Analysis Load Cases

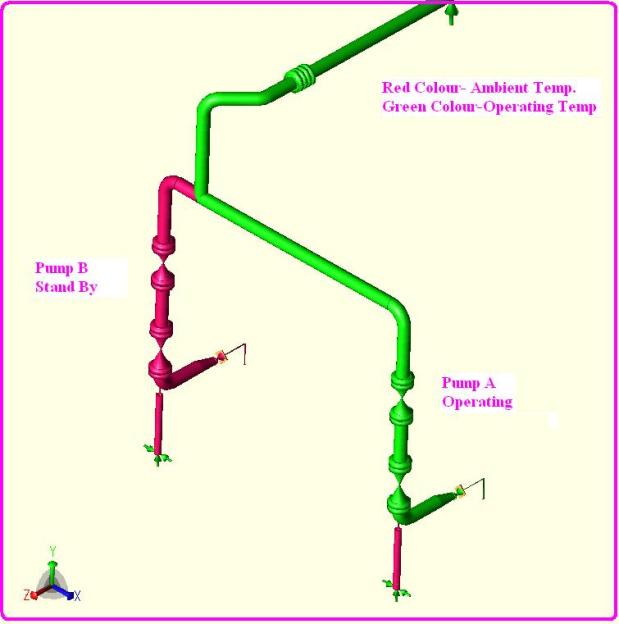

Along with normal load cases, two additional load cases need to be prepared. Normally in the refinery and petrochemical industry, one pump operates and the other pump acts as a stand-by pump. So we have prepared load cases as follows:

1. Hydrostatic case (WW+HP HYD)

2. Operating case with both pumps operating (W+T1+P1 OPE)

3. Operating case with the total system in maximum design temperature ( W+T2+P1 OPE)

4. Operating case with pump A operating and pump B Stand by (W+T3+P1 OPE)

5. Operating case with pump B operating and pump A Stand by (W+T4+P1 OPE)

6. Operating case with the total system in minimum design temperature ( W+T5+P1 OPE)

Next all normal load cases like static seismic, static wind, etc are to be built as per stress analysis or flexibility specification.

When pump A is in operating condition and pump B stand by, the normal pipe operating temperature has to be inserted till the Tee connection for pump A and ambient temperature will be the input for pump B as shown in Fig. 4. Similarly, reverse the input when pump B is operating.

After the equipment is modeled completely start modeling the piping following dimensions from piping isometric drawings. Try to make a closed system. Normally pump lines are connected to some vessel, tank, or heat exchangers. So it will create a closed system. Then run the analysis to check stresses, displacements, and loads.

Analyzing the output Result

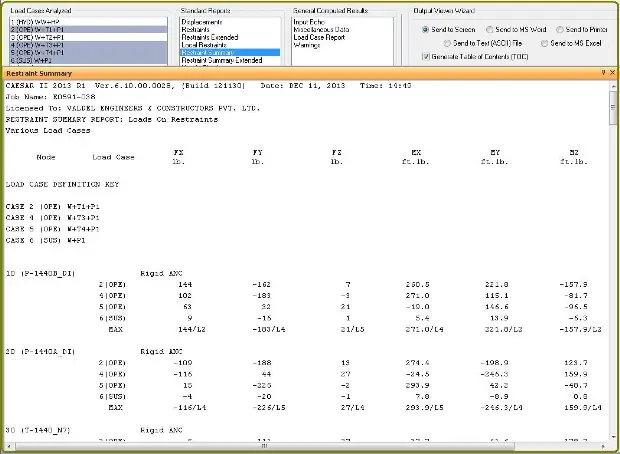

Once Caesar completes its iteration process we can see the output results in the output window. At nozzles (the nodes which we anchored with a CNode) we can check the force values. These values we have to compare these with the allowable values. If the actual values are less than the allowable values then the nozzle is safe. Otherwise, we have the make changes in supporting or routing to bring the nozzle load values within allowable. A sample output restraint is provided in Fig. 5 for your reference.

As can be seen from the above figure we are checking nozzle loads in load cases 2, 4, 5, and 6. For rotary equipment, normally nozzle qualification in design or upset temperature is not required.

Special Consideration for Rotary Equipment

Now we have to make one separate caesar file and we have to check sustained displacement at the nozzle at WNC (weight no content) case. This checking will ensure proper alignment of the piping flange and equipment nozzle flange. For detailed alignment check analysis steps, follow this link: https://whatispiping.com/alignment-check-methodology

Always remember to provide the first piping support from the pump nozzle as adjustable support (or a spring hanger support) to aid in alignment.

In the case of 3 pump systems, normally two pumps will be operating and one pump will be stand by. So input and prepare load cases accordingly. If you have any confusion or want to add more please write in the comments section.

Video Tutorial for Pump Piping Stress Analysis

The following video explains the pump piping stress analysis methodology for 3 pumps in detail.

Few more pump-related articles for you..

Cause and Effect of Pump Cavitation

Major Factors Affecting the Pump Performance

NPSH for Pumps: Explanation and Effect

Water Hammer Basics in Pumps for beginners

Mechanical Seals for Rotary Pumps

Pumps & Pumping Systems: A basic presentation

A brief presentation on “CENTRIFUGAL PUMP WITH SPEED CONTROL”

Considerable points while Commissioning and starting-up a Process Pump

Considerable points while installing centrifugal pumps at site to reduce vibration

the temperature distribution between Isolating valve and Tee section ambient of stagnant condition(I consider (T+Tamp)/2)?

when Pump B is stand by it doesn’t make any effect? while Pump A is standby itz make influence on nozzle as it is long section.

Average temp philosophy is considered if the line is insulated. Otherwise in the long run the temp will drop and reach almost ambient condition..

Hi, anup

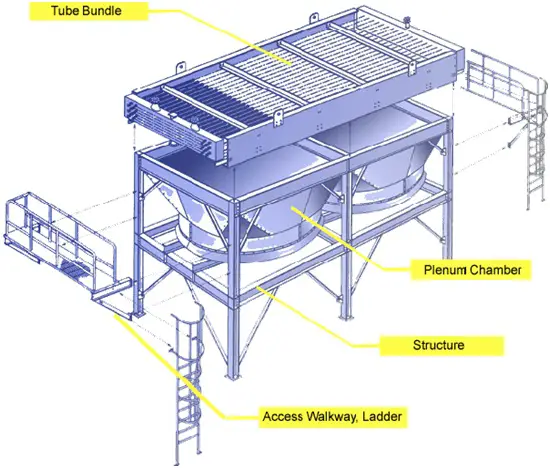

Can you provide the stress analysis method for air fin cooler.

I’ve learn a few good stuff here. Certainly worth bookmarking for revisiting.

I wonder how a lot effort you put to make

one of these excellent informative website.

I totally agree with you.

It’s not my first time to pay a visit this website,

i am browsing this website dailly and get good information from here

every day.

hello there and thank you for your info – I’ve certainly picked up

anything new from right here. I did however expertise several technical

points using this website, since I experienced to reload the web site lots of

times previous to I could get it to load properly.

I had been wondering if your hosting is OK? Not that I am complaining, but slow loading instances times will often affect your placement in google and

could damage your quality score if advertising and

marketing with Adwords. Well I am adding this RSS to my email and can look out for much more of your

respective exciting content. Make sure you update this again soon.

I can not understand the concept behind considering temp. T3, T4 T5.

Usually we consider same temp. for both the pumps , will it make any difference ?

Few Nice insights on this topic is provided by Mr. David Diehl and Mr. Edward Klein in linkedin. The original comments by them can be accessed by following the link mentioned at the end. However for convenience of the readers I am producing those in this section.

By Mr. Edward Klein:

Senior Pipe Stress Engineer at S & B Engineers and Constructors, Ltd.

While the overall article is good, I do have a couple of points.

First, the guides shown on the base supports in front of the pump are a modeling practice that I strongly discourage. These guides are a “paper solution” as their proximity to the pumps, along with a typical installation gap and relatively low stiffness compared to the pump casing means that any loads that Caesar shows them carrying will in reality be applied to the pump nozzles. We can certainly make a case that pump vendors excessively handicap us with the allowables published in API and ANSI, but they are what we have to work with. Those guides may show you qualifying in your model, while the actual pumps are over loaded.

Also, while we also employ as standard the modeling practice of treating the piping for the idle pump as ambient, there are cases with hotter pump systems that need to be considered. Often, hot operating systems will have a warm up bypass around the check valve to backflow a small stream through the idle pump. The purpose of this is to keep the idle pump in a ready condition and to avoid the potential for cracking induced by thermal shock. In these systems, we take the normal case for nozzle qualification with both pumps at temperature. There can still be times when one side is closer to ambient if the pump is taken out for maintenance, but these become more of a temporary upset case, rather than the long term exposure to loads that the allowables are intended to protect the pumps from.

Finally, I’ve generally moved away from the habit of modeling a rigid vertical element from the pump center to the base. API horizontal pumps are centerline supported anyway. ANSI pumps are foot mounted. Yet, even in this case, I find it creates an exaggerated effect due to the stiffness values of restraints and rigids in the model and the fact that we typically model piping as supported at its centerline, even though the support points are at the bottom of the pipe.

By Mr. David Diehl

Director of Training at Intergraph|Training & Communications Executive|Leadership & Organizational Development

CAESAR II now provides a nozzle check report in the static output that compares identified nozzle loads to limits provided in standards. This screening report is more convenient than referencing the restraint report as you show.

Also, some would question the sudden temperature changes defined for the header but your approach is conservative and similar to the recommendations in WRC 449.

The actual comments can be accessed from the below mentioned link:

https://www.linkedin.com/groupItem?view=&item=5970565094302560257&type=member&gid=2024452&trk=eml-group_discussion_new_comment-discussion-title-link&midToken=AQH3kT0n6EEJKA&fromEmail=fromEmail&ut=3aANfDQNxo56E1

Normally for Nozzle load checking shall we consider the seismic effect and wind effects loads case also…

give me the suggestion pls

This is big problem

I do not see many comments here, it means you have low visitors. I know how to make your page go viral. If you want to know just search in google for:

Kimting’s Method To Go Viral

Hi to all, it’s actually a nice for me to pay a quick visit this web site, it contains useful Information.

Problem:

Of a 3-pump systems, 2-pumps are runnng at all time while the third one is a standby.

All three pumps are shaking violently like they will be thrown of off the foundations.

Caesar stress analysis recommends some piping and support modifications based on the results.

My question is how wise it is to delve into modifications based on the result recommendations?

Shouldn’t we do CFD as well and then should perform some kind of correlation study before we spend any money on the actual modifications?

Hi Gsky

Did you find any solution for standby pump and how mitigated the vibration issue?

Did you carried out CFD or piping alteration was done as per Caesar II outcome.

I am happy to know about your experience and your troubleshooting story.

You can share your kind words @ anuraagkumaarhd@gmail.com

Thanks buddy

Hi. Can any one please send me the above caesar model on adnanaf@outlook.com.

Nice Blog .Thanks for sharing.

Can you please show how to analyze your system with using springs cans in the one pump on/off scenario?

i didnt understand the 10-5000 8.5 inch please in detail

as I heard from my senior, it is common practice to multiplied by 4 of line size and thickness too in modelling rigid pump. how about your comment for this statement? thanks sir.