This article is intended to serve as a guide in the development of equipment layout and piping layout for centrifugal compressors and their associated equipment, with the goal of producing safe, operable, economical, and maintainable installations.

Compressors are machines, which are used to increase the pressure of a gas by mechanically reducing its volume within the compressor casing.

Compressor Types

- Positive Displacement Compressors

- Reciprocating compressor

- Screw Compressors

- Centrifugal compressors

- Pipeline compressors

Type of Compressor Drives

Following are the various types of Compressor drives:

- Electric Motor Drives

- AC Squirrel Cage Induction Motor

- Synchronous AC Motor

- Gas Turbines

- Steam Turbines

- Variable Speed Drives

- Variable Frequency Drive

- Variable speed (Hydraulic Coupling) Drives

Auxiliary Equipment’s

- Lube Oil Cooler (Supplied by Compressor Vendor)

- Lube Oil / Seal Oil Console (Supplied by Compressor Vendor)

- Surface Condenser

- Condensate Pump

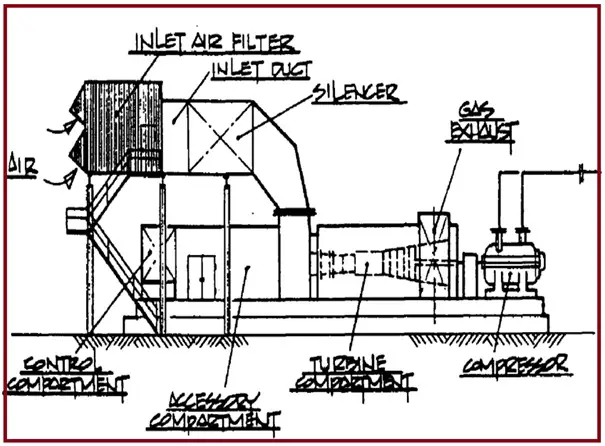

- Inlet Air Filters (Supplied by Compressor Vendor)

- Suction Scrubber (Upstream of Compressor)

- Air Cooler (Downstream of Compressor)

- Discharge Scrubber (Downstream of Air Cooler)

Compressor Layout

- When locating compressors, consideration must be given to accessibility, maintenance, and loss prevention requirements.

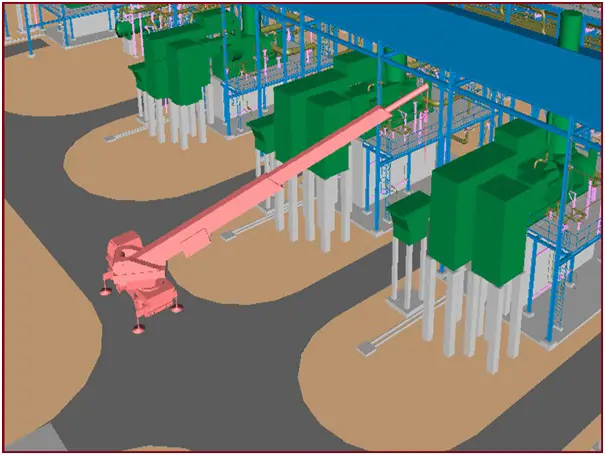

- There must be a Vehicular (Crane / Fork Lift Truck) Access-way on at least one side of the installation. Refer Fig. 1

- A compressor is generally located inside Shed with the provision of a Mono-Rail or EOT Crane for Maintenance. The capacity of the crane is to be decided based on 150% of the highest weight of the component to be lifted. To be checked with the compressor vendor.

- A compressor can be installed in a Series and Parallel arrangement.

- The minimum Distance between two Adjacent Compressors shall be 10m.

- Generally, Compressors are Grade Mounted (Fig. 2). But Process criteria/requirements will decide if it should be grade mounted or elevated

Compressor Piping Layout

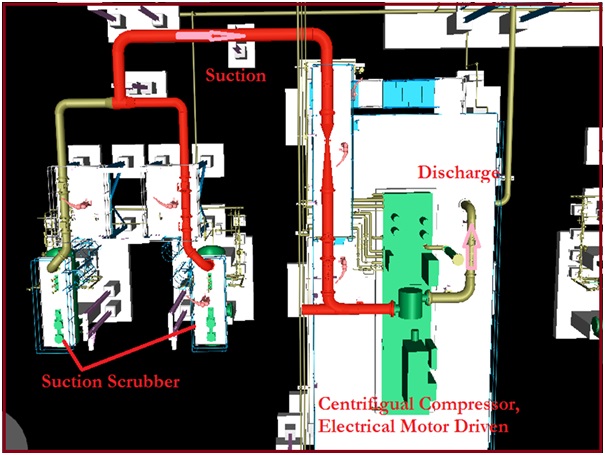

Suction & Discharge Piping (Fig. 3)

- Compressor Suction Piping Shall be as Short as Possible.

- Compressor Suction Piping should have Inlet Filter / Strainer. It can be Temporary or Permanent

- Suction Piping should be sloping/free draining towards Inlet Scrubber

- Suction lines require a minimum straight run of piping upstream of the suction nozzle which varies between 3 and 8 times the normal pipe size. (Vendor requirement)

- All operating valves must be readily accessible, preferably from grade.

- All lines to the Compressor shall be provided with break-up flanges for Maintenance.

- Compressor Suction Line Flowmeter: Suction routing shall be such that Upstream and Downstream straight lengths shall be sufficient for the performance of the Flowmeter

- Isometrics – Both Suction and Discharge piping should have been noted for “Pickling and Passivation” i.e. Chemical cleaning of Lines before commissioning.

- Anti-Surge Valve Is Designed and Supplied by Compressor Vendor.

- Input to Compressor Vendor for Designing / Sizing the Anti-Surge Valve is given by piping, by providing suction and discharge length.

- Anti-Surge Valve is located on the Anti-Surge line which is basically a by-pass / recirculation line between Compressor Suction and Discharge Piping for Surge control

- Anti-Surge Valve shall be located at Highest Point and shall be free draining on both side

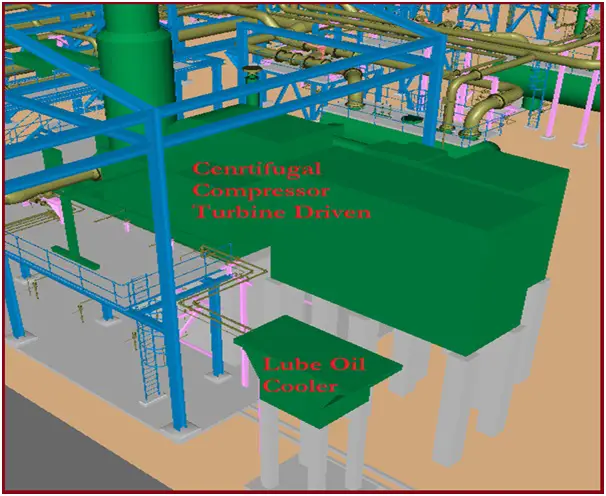

Lube Oil Cooler & Piping (Fig. 4)

- Lube Oil Cooler Shall be Accessible from Road.

- Lube Oil Cooler Shall be located as close to Compressor as Possible.

- Lube Oil Cooler Piping Should Not Interfere with Access and Maintenance space.

- Lube Oil Cooler line must be Free Gravity flow requirements.

- Lube Oil Cooler Piping Should have Break-up Flanges for Maintenance purposes.

- Lube Oil Cooler Isometric should also have noted for “Pickling and Passivation” i.e. Chemical cleaning of Lines before commissioning.

Supporting Compressor Piping

- The first support from Compressor Suction and Discharge nozzle is either Spring support or Adjustable support for Alignment during Construction / Erection.

- Compressor piping should never be supported by the Compressor foundation. Pipe supports must be provided with independent foundations to avoid transmission of vibration.

- Compressor Suction / Discharge Piping should be routed in such a way that it has enough flexibility to accommodate Thermal Expansion and Reduce the Nozzle Load.

- Compressor Suction / Discharge Piping should be adequately supported as per Stress Engineers’ Support requirements.

- Process Should be consulted for any possibility of two-phase flow/slug flow and the line should be supported accordingly

- As compressors are meant for Gaseous fluid, the Hydro-test load on supports may be very high for big bore lines. Hence we can recommend Temporary supports to be erected during Hydro-testing with the help of a Stress Engineer.

Utility Requirements

The following are the utilities required for the Compressor:

- External Fuel gas for seal gas system

- Instrument Air for the Instruments/Control system/Seal gas system

Applications of Compressors

- Refineries

- Natural Gas Compression & Transportation Services

- Oil Exploration – Gas Reinjection, Gas lift, etc.

- Gas Liquefaction

- Air Compression service

- Refrigerant compression service

- Refueling applications

Few more useful resources for you…

Articles related to Compressor

Articles Related to Pumps

Piping Design and Layout Basics

Piping Stress Analysis Basics

Piping Materials Basics

Articles Related to Mechanical Design

Articles Related to Process Design

Articles Related to Heat Exchanger

You should put your piping system design work into a publication like the piping guide. Addition of stress analysis with a program like Caesar 2 would be a great addition to the guide.

Great work and Thankyou

HELLO Mr. Anup Kumar Dey,

I enjoyed reading your articles. my name is Mr.A.P.NANJAPPA, BASICCALLY i AM ELECTRICAL ENGINEER TUENRNED INTO automation- Project engineering i power plant-refineries -ethylene oxide plant-gas comprressor,turboexpanders, 250mw gas turbeine generators- bunkering loading arms- steell plant pelletizing, iron & steel plant -eaf ..

I work in Iran ,Now I have returned to India.Live in bangalore.

how do you present your articles in Blog.do you need make any payments-we should follow any regulations for publications.i have 33 papers published in international power system conference. but I have some practu=ical and soft ware hints collected through my experience.

please guide me

thank you

nan