What is Pump Cavitation?

Pump cavitation is a destructive issue that can generate excess noise and energy usage to serious pump damage. The problems of pump cavitation are not new and ever-growing. It seriously affects the pump operation and lifespan. However, pump cavitation can be easily avoided with the right planning and troubleshooting.

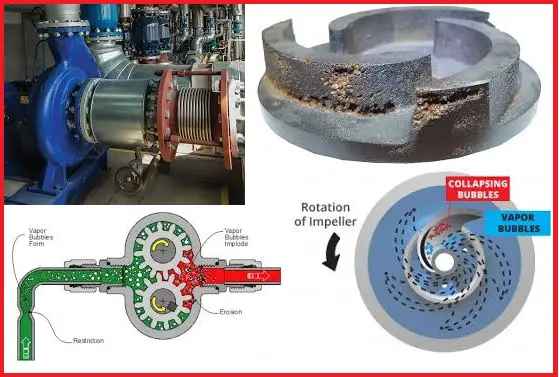

Cavitation is an important term for rotating equipment engineers. The generation of vapor bubbles or cavities in a fluid flow due to low pressure and its sudden collapse causing damages in the related parts like the impeller, pump housing, etc are termed as Cavitation. It is one of the major problems for Centrifugal pumps. There are various criteria that can describe the occurrence of cavitation, its extent, and its impact of it.

Cavitation occurs when the liquid in a pump creates air bubbles because of the partial pressure drop of the flowing liquid. Insufficient net positive suction head available is the main cause of generating air bubbles. Changes in the liquid pressure in the pump turn the liquid into vapor. As the liquid moves by the pump’s impeller spinning, the air bubbles move and instantaneously implode. The collapse of vapor bubbles creates a shockwave that erodes the impeller surface. When strong cavitation occurs at the impeller inlet, the pump performance decreases, leading to even pumping failure.

Pump Cavitation is usually common with centrifugal pumps as these types of pumps work by changing the pressure inside the unit to create a vacuum, pushing the liquid into the unit as opposed to pulling it in. Cavitation in submersible pumps is less frequent.

What Causes Cavitation?

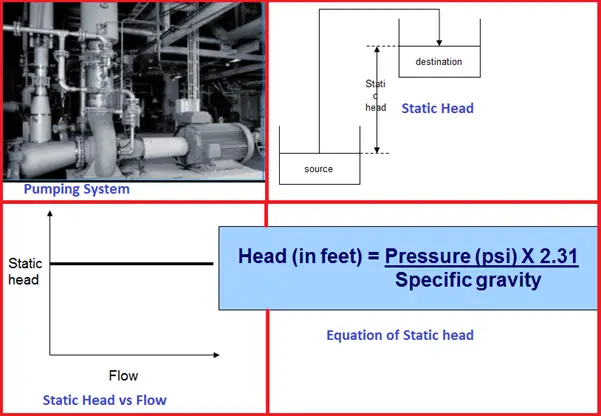

When the suction pressure drops below a certain value, the performance of the centrifugal pump deteriorates. This suction pressure that is often decided with respect to vapor pressure at suction temperature is called Net Positive Suction Head which is popular by its acronym NPSH. If this NPSH drops, impeller inlet pressure may fall below the vapor pressure which causes vapor bubbles or voids to generate. If the flowing liquid is then subjected to pressures above the vapor pressure, these voids can implode causing damage, which is called cavitation.

The most well-known causes of cavitation are:

- Not meeting the required NPSH

- The pump is installed at too high of a distance above the fluid source

- The suction pipe diameter is too small

- Pipe blockage on the suction side

- Clogged or obstructed filters

- The length of the Suction pipe is more.

- Excessively high suction lift.

- Poor piping design

- Flowing liquid is having a very low vapor pressure

- Fluid is overly heated to the point of vaporization.

- The pump is running too far right on the pump design curve

- The Pump Speed is more

- Due to a high-vacuum or low-pressure environment, the flow in the pump is not proper.

- High discharge pressure.

- Poorly specified pump.

Cavitation Types

Two types of cavitation are more prevalent in rotating equipment engineering; Vapor Cavitation and Gas Cavitation.

Vapor Cavitation

When the static pressure in a flowing fluid falls below the vapor pressure, Vapor cavitation develops. At the same time, the presence of nuclei or microscopically small vapor bubbles are required for the cavitation to form. The static pressure decreases if the local velocity is increased or the inlet conditions change.

Now, the generated vapor bubbles implode suddenly at a very high velocity, when the static pressure rises above the vapour pressure in the flow direction. This sudden implosion may lead to material erosion, a rise in noise levels, rough running of the pump, and a drop in pump efficiency and head. Normally, as the implosion begins, vapor bubbles will dent inwards, and later a water microjet is formed that is directed at the wall and strikes with a high velocity. This sequence of all events, along with with the fissured microstructure, very fine pores, indentations, and cracks in the wall surface is the main reason behind the material’s destruction, which is accelerated in the presence of mechanical stress.

Gas Cavitation

When the bubbles are generated due to the release of dissolved gases from the solution in conjunction with diffusion, Gas Cavitation occurs. When the fluid’s pressure drops below the saturated vapour pressure, Dissolved Gases come out from the solution. This mechanism is dependent on the concentration of the dissolved gases. In terms of material damage, Gas cavitation is not as destructive as vapor cavitation, because, with rising pressure, the gas diffuses into the liquid again which means that this process is much slower than the collapse of vapor bubbles.

The formation of Vapour and Gas may overlap, as well. Vapor bubbles which are generated when the fluid’s pressure reaches or drops below vapour pressure may also contain gas that can release from the solution via diffusion while the fluid approaches the suction of the pump. So both of these two cavitations together, intensify the extent of the impact on the fluid flow.

Depending on the location of pump cavitation on the suction or discharge side, pump cavitation can also be grouped as Suction cavitation and discharge cavitation.

Symptoms/ Effects of Cavitation

As a result of cavitation, One or a combination of the following symptoms or effects can be generated:

- Unexpected Vibrations

- Pump performance deterioration. Decreased or Reduced Flow or Pressure

- Erosion of the Impeller

- Seal and Bearing Failure

- Erratic Power Consumption

- Distinct Noise.

- Mechanical damage.

How to Prevent Cavitation?

An obvious way to guarantee that there will be no pump cavitation is to restrict the void or bubble generation. This can be done in various ways like

- Lowering the pump speed.

- Raise the liquid level to increase the NPSH so that a lower pressure scenario does not occur.

- Lowering the operating temperature.

- Reduction of Pump motor RPM. Running the pump at the ideal rpm.

- Using a booster pump to feed the principal pump.

- Increasing the impeller diameter.

- To properly operate a pump best suited for the application

- Selecting the impeller inlet geometry that ensures no vapor formation.

- Using two lower capacity pumps in parallel.

- Installation of an impeller inducer

- Strictly following the pump’s manufacturer performance guidelines.

- Increasing pump suction line size.

- Altitude or height has a major effect on pump cavitation. At higher altitudes, special care must be taken to make sure that cavitation does not occur since liquids boil at a much lower temperature.

- The fluid temperature needs to be monitored to keep cavitation under control.

- Avoiding pockets for air or vapor accumulation.

- Keeping pipe reducers as close to the pump as possible.

- Regular pump maintenance.

- Installing the pump at the proper location

Few more resources for you..

MAJOR FACTORS AFFECTING THE PUMP PERFORMANCE”: A short article

NPSH for Pumps: Explanation and Effect

Water Hammer Basics in Pumps for beginners

Pumps & Pumping Systems: A basic presentation

A brief presentation on “CENTRIFUGAL PUMP WITH SPEED CONTROL”

Stress Analysis of Pump Piping (Centrifugal) System using Caesar II

Considerable points while Commissioning and starting-up a Process Pump

Considerable points while installing centrifugal pumps at site to reduce vibration

Reference and further Studies

- KSB Knowledge Bank.

- https://oaktrust.library.tamu.edu/handle/1969.1/164365

- https://www.globalpumps.com.au/blog/what-is-pump-cavitation-and-how-to-prevent-it

I really appreciate this wonderful post, Thank you.

Speaking of the solution to prevent Cavitation you talked about increasing the diameter of the impeller but according to affinity laws D1/D2 = N1/N2 that will increase the pump speed !

So are we talking about the impeller diameter or the impeller eye diameter

Your articles so interested much simpleton understand also no complication in vocabularies used finnaly through your articles I’ve understand a lot since before I was just feeling without understanding..