What is a Pressure Vessel

A pressure vessel is a closed leak-tight container (normally cylindrical or spherical) designed to hold fluids (i.e, gases, liquids, or two-phase fluids) at a pressure substantially different (higher or lower) from the ambient pressure. They are usually made from carbon steel or stainless steel and assembled from plates by welding method. However, other materials like Aluminium, copper, non-metals, etc also find usage as pressure vessel material in some specific situations. Even though most pressure vessels are basically long cylinders with two heads at both ends, they can take the shape of a sphere or cone.

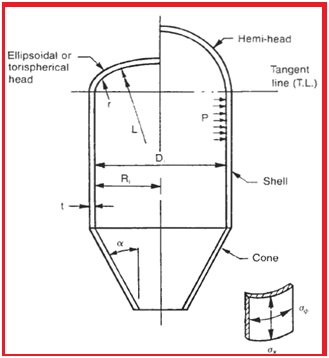

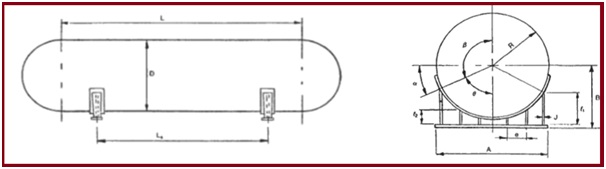

Examples of some widely used pressure vessels are columns, boilers, separators, knock-out drums, Towers, Bullet Tanks, Reactors, and Heat Exchangers. All these pressure vessels are extensively used in the oil and gas, petroleum refining, and chemical/petrochemical processing industries, and power plants have varying operating pressures and temperatures. However, note that an atmospheric storage tank is not a pressure vessel. Fig. 1 shows a typical pressure vessel used in the oil & gas industry.

What are the Types of Pressure Vessels?

Pressure vessels are classified based on various different parameters which are covered here.

Based on their installation/orientation they are classified into the following two groups.

- Vertical pressure vessel

- Horizontal Pressure Vessel

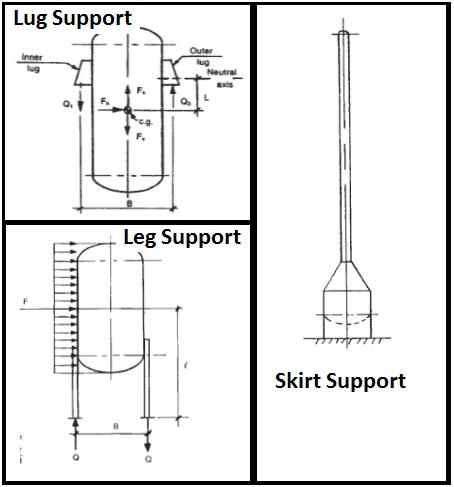

Various methods are used to support pressure vessels, like

- Lug Support

- Ring Support

- Skirt Support

- Leg Support

- Saddle Support

Types of ends attached to the vessels are

- Dish ends

- Conical ends

- Flat Ends

Fig. 2 shows the general configuration of a pressure vessel.

Inputs for the Design of Pressure Vessels

The design of pressure vessels must be done with utmost care as these operate under immense pressure. A ruptured pressure vessel can cause serious irreversible harm to mankind and properties. Normally the ASME Sec VIII code governs the design of pressure vessels.

The following inputs are required for pressure vessel design

- Internal Design Pressure / External Design Pressure

- Test Pressure

- Design temperature

- Material of constructions

- Type of support

- Type of loading (wind load/seismic loading/snow loading)

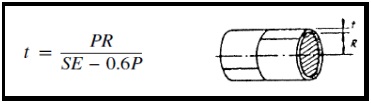

Pressure Vessels Design Formula

The basic formula for designing the cylindrical shell is

σ = PD/2t

Therefore, t = PD/2σ

Where,

- t = thickness of the shell

- P = internal pressure

- D = diameter of the shell

- σ = tensile stress

This basic formula is modified in international design codes.

For ASME BPVC Sec VIII, the thickness of the cylinder is calculated by the following formula (Fig. 3)

Where,

- t = thickness of the shell

- P = internal pressure

- R = radius of the cylinder

- S = tensile stress

- E = joint efficiency

Refer to ASME Sec VIII Div 1 for design formulas for all sections of the vessel/cylinder. The following figure provides a typical flow chart for pressure vessel design steps.

Type of Pressure Vessel Supports

Based on how the pressure vessels are supported, they can be of the following types.

- Vessel Supported on Lug Support (Fig. 5)

- Vessel Supported on Skirt(Fig. 5)

- Vessel Supported on Leg(Fig. 5)

- Vessel Supported on Saddle(Fig. 6)

Pressure Vessel Parts

A pressure vessel consists of the following parts

- Shell, head

- Nozzles

- Flanges

- Gaskets

- Internals

- Platforms & ladders

- Skirt or saddles

- Baseplate

Click here to know more about major pressure vessel parts.

Design codes used for Pressure Vessel Design

There are various codes that are used for pressure vessel design, construction, and maintenance purposes. Some of them are listed below:

- EN 13445: The current European Standard, harmonized with the Pressure Equipment Directive (97/23/EC). Extensively used in Europe.

- ASME Code Section VIII, in addition, is supported by Sections II (materials), V (NDT/NDE), and IX (welding). Published by the American Society of Mechanical Engineers.

- ASME Code Section VIII Division 1: US standard, design by the formula. Almost exclusively used in North America, widely used worldwide.

- ASME Code Section VIII Division 2: Alternative Rules, design by analysis.

- ASME Code Section VIII Division 3: Alternative Rules for Construction of High-Pressure Vessel

- BS 5500: Former British Standard, replaced in the UK by EN 13445 but retained under the name PD 5500 for the design and construction of export equipment.

- AD Merkblätter: German standard, harmonized with the Pressure Equipment Directive.

- EN 286 (Parts 1 to 4): European standard for simple pressure vessels (air tanks), harmonized with Council Directive 87/404/EEC.

- BS 4994: Specification for design and construction of vessels and tanks in reinforced plastics.

- IS 2825-1969 (RE1977): code unfired Pressure vessels

Pressure Vessel Internals

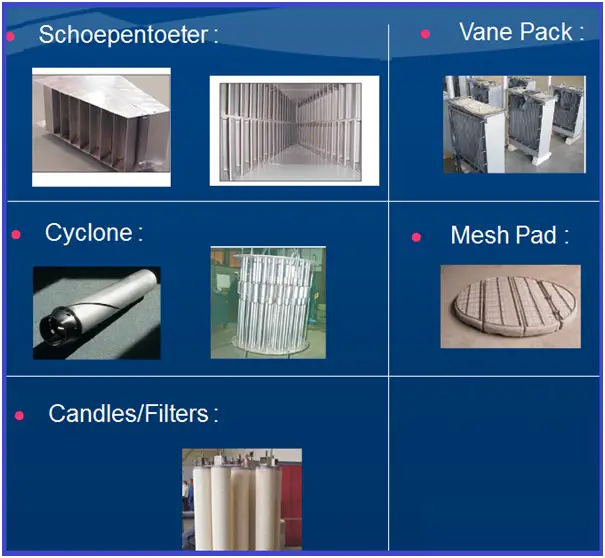

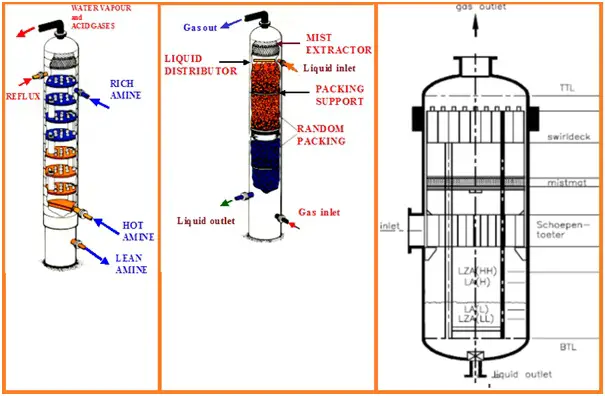

Internals are used to separate the liquid from a mixture of liquid & vapor. Refer to Fig. 6

Example of Pressure Vessels

Fig. 7 shows a few of the various types of pressure vessels that are normally used in plants.

- Separator

- Scrubber

- Distillation Column

- Shell & Tube Heat Exchanger

- Reactors

- Knock out drums

- Towers

- Bullet Tanks

Material of Construction of Pressure Vessel

For industrial applications, the following materials are widely used for pressure vessel construction. However custom-made pressure vessel fabrication is possible depending on requirements.

- Carbon steel and Cladding Plates

- Low and High Alloy Steels

- Stainless Steel

- Manganese Steel

- Duplex Stainless steel

- Aluminum, Copper, Nickel Alloys

- Fibre Glass Reinforced Plastic

Applications of Pressure Vessel

Pressure Vessels are most widely used in the following sectors

- Refinery and Petro-chemical

- Fertilizer

- Oil and Gas

- Chemical

- Power Plants

Regular inspection of pressure vessels is very important to avoid pressure vessel failures. API 510 provides guidelines for pressure vessel inspection.

The following video provides a comprehensive basic of the pressure vessel design methodologies:

Few more Resources for you.

Brief Explanation of Major Pressure Vessel Parts

A Presentation on VESSEL CLIPS or VESSEL CLEATS

10 points to keep in mind while using project-specific pressure vessel nozzle load tables during stress analysis

Understanding Pressure and Temperature in the context of Pressure Vessel Design

A video tutorial on “Comprehensive Design Code Coverage for Pressure Vessel and Heat Exchanger Design” by Bentley Institute

Reference

https://faculty.washington.edu/vkumar/me356/pv_rules.pdf

Online Course on Pressure Vessels

If you wish to learn more about Pressure Vessels, their design, fabrication, installation, etc in depth, then the following online courses will surely help you:

Very good presentaation. Congratulations.

I don’t have much to say about this wonderful piece of work…just blessings….am a chemical engineer in making in my final year

Superb presentation..

This was a Perfect Overview….

A useful presentation.

Thanks & Regards

I don’t have much to say about this wonderful piece of work….just blessings only…am a chemical engineer in making …in my final year at campus

Good explanation Mr. Anup sjr, it is too useful for me for preparing for interview in pressure vessel manufacturing company ..thank you !

It would be better if you have shown simple vessel design using hand calculation or software

Very good, useful information.

Pl.publish article on design of vessels under external pressure with an example. ( Pl clarify whether we can design vessel for partial vacuum?)

Superb in short.. Excellent present

This was a Perfect Overview….

Useful information.

Simply put, clear and precise, thanks…

Clear explanation. And let your journey continue

IT was really Nice. Thank you Sir

Thank you a lot

The blog is very informative

I came across your website. It’s awesome.

YOUR PRESENTATION IS VERY AWESOME & USEFULL.

WELL DONE.

overall a good overview of pressure vessel it would have been complete if you had included the dish end details and allowance to be considered during design